Engraving on slabs

Posted on in unusual materialsEngraving lettering, logos, or other imagery into large wood slabs is something we are asked to do from time to time. Often the customer is planning to fill the engraving with resin for an inlaid look, or paint for contrast. We usually see conference tables, dining tables, plaques, and benches done with this treatment. It is also possible to combine engraving and inlays. In the piece shown below, we engraved the lettering and outlines, and inlaid two colors of acrylic as well as painting the engraved areas on both the wood and acrylic.

For engraving cuts onto slabs, the slab must first be flat, or as flat as the customer wants. Thus, planing must be completed first, as well as any desired crack repair or joining for width. We first place the slab on the table and get the top as flat as possible. If the bottom of the slab is not quite flat, it may wobble, and the vacuum table will not hold it well due to the air gap underneath. Once it is shimmed, wedged, and taped sufficiently, we will take bit height measurements at several points on the slab to find the average height, which we'll program into the CNC router for each bit that will be used in the cut.

Depending on the specifics of the design to be engraved, we might use flat endmills, V bits, or ball nose bits. Often the cuts will be filled with resin so the important result is the edge of the cut. Other times the cuts will be painted on the inside, and we can mask the surface prior to cutting, if desired, to make the painting process easier. Sometimes, of course, the customer will do nothing further but put a finish on the slab to show off the inherent beauty of the wood itself, and the cuts in this case must be perfect, without tearing or raggedness on the interiors.

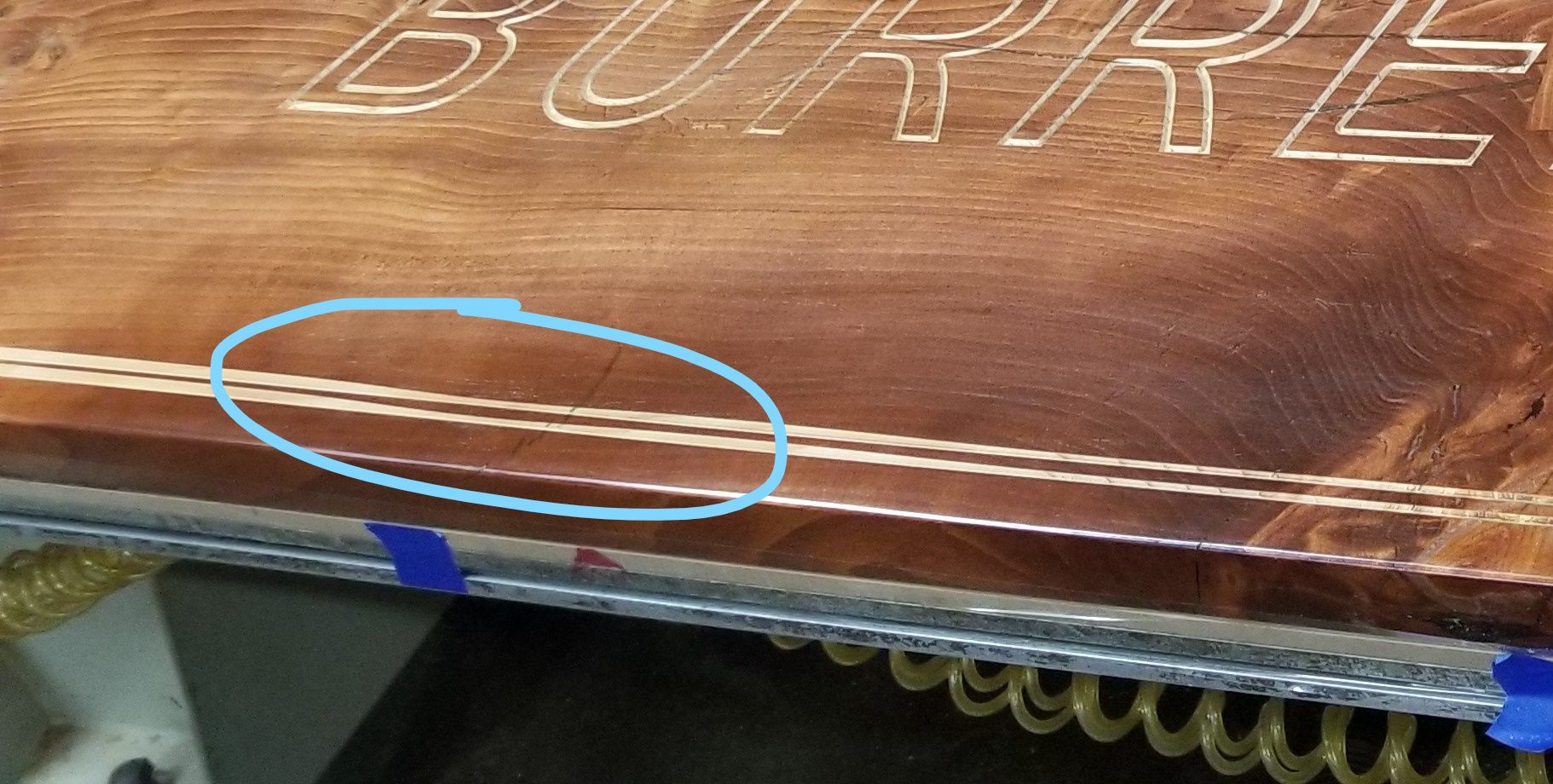

When small lettering is required, or other intricate detail, we often recommend a V bit, which can create sharp inside corners by changing the height of the cut. The shallower the cut by a V bit, the smaller the width of the removed material, and this can reach quite a sharp point when the V bit's tip is cutting just barely below the face of the slab. An issue that arises here sometimes is when the slab is not quite flat, and has lower and higher spots. A V bit cut that is the same depth from the machine's point of view, will appear to be wider and thinner again as it moves from a higher to a lower spot on the slab, as can be seen in this photo. If this is significantly undesirable to the finished piece, it can be altered by hand, carefully, with a chisel or carving knife, although unfortunately Neal's is not able to offer this risky hand work.

For engraving into irreplaceable slabs, it is our policy to always do a test cut to verify the cuts. The purpose of the test is not to create a beautiful result, but to find any errors in the drawing or coding, which could ruin an irreplaceable piece of wood.

Engraving slabs takes time and can be costly, but with care we can achieve an excellent result.